PRODUCTION AND DISTRIBUTION MANAGEMENT

The type of a textile item, fabric or knitted fabric is not the only element determining its placement in the suitable factory. The essential factors are quality, quantities, certificates, finishing and target pricing. Factories and their machines are classified according to diverse categories, be it knitted fabric, fabric, high quality items or fire-resistant work uniforms.

Depending on a product, we can guide you towards specialized factories for textile production (woven, knitted, non-woven), sportswear (sewn and circular woven), menswear, womenswear and childrenswear.

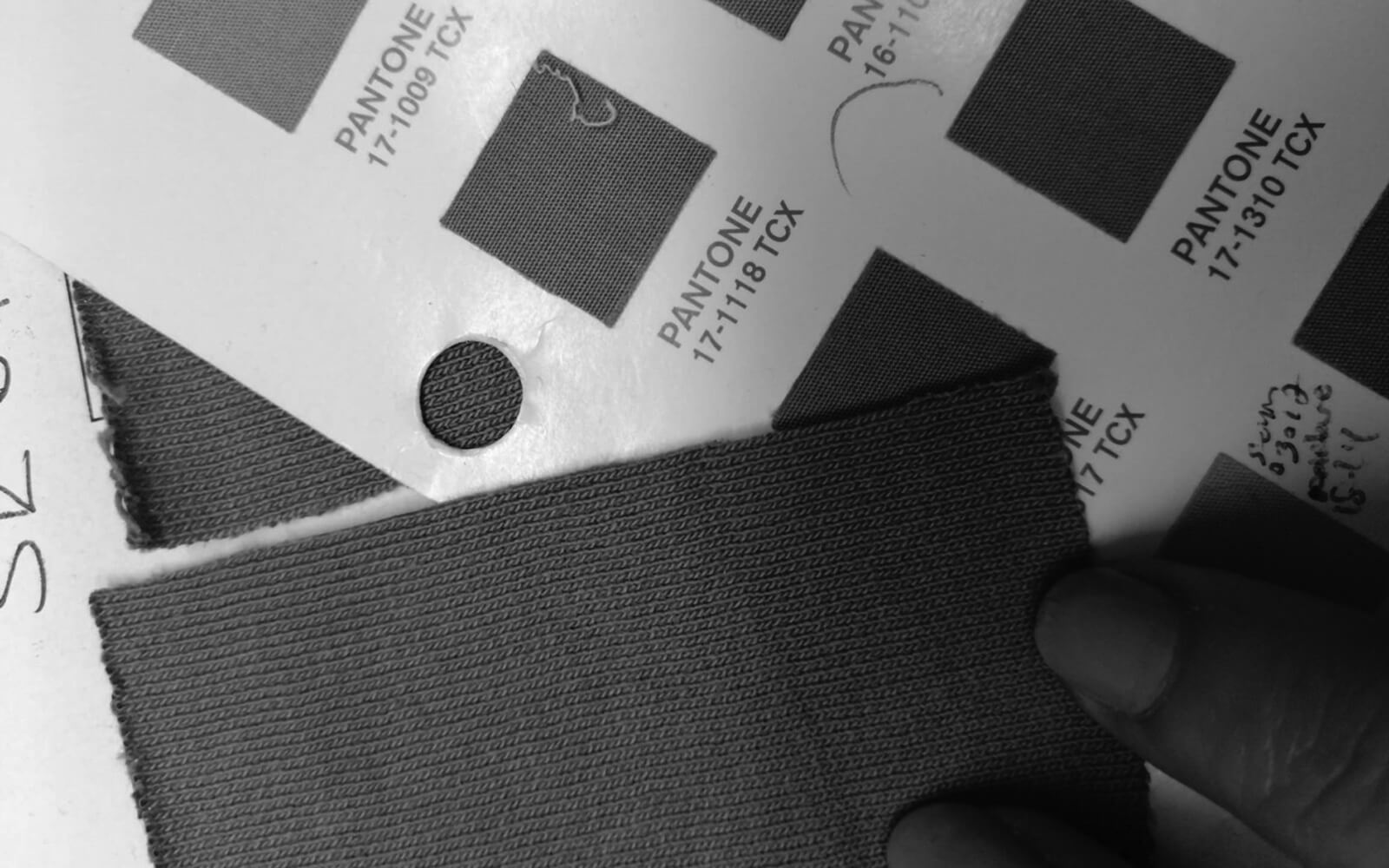

Technical packs are the ‘ID’ of every product and are vital to initiate the process. They contain information about material, properties, finishing, sewing, colours, size range, measurements and gradation. Technical packs enable you to determine precise dates of delivery, production duration, production course and pricing.

Having been outlined in detail, they are given to the factory, so that the initial sample can be prepared.

Once the samples have been confirmed and the dates set in the factory, production can begin. Specifications given in technical packs serve as guidelines for the entire process in the factory.

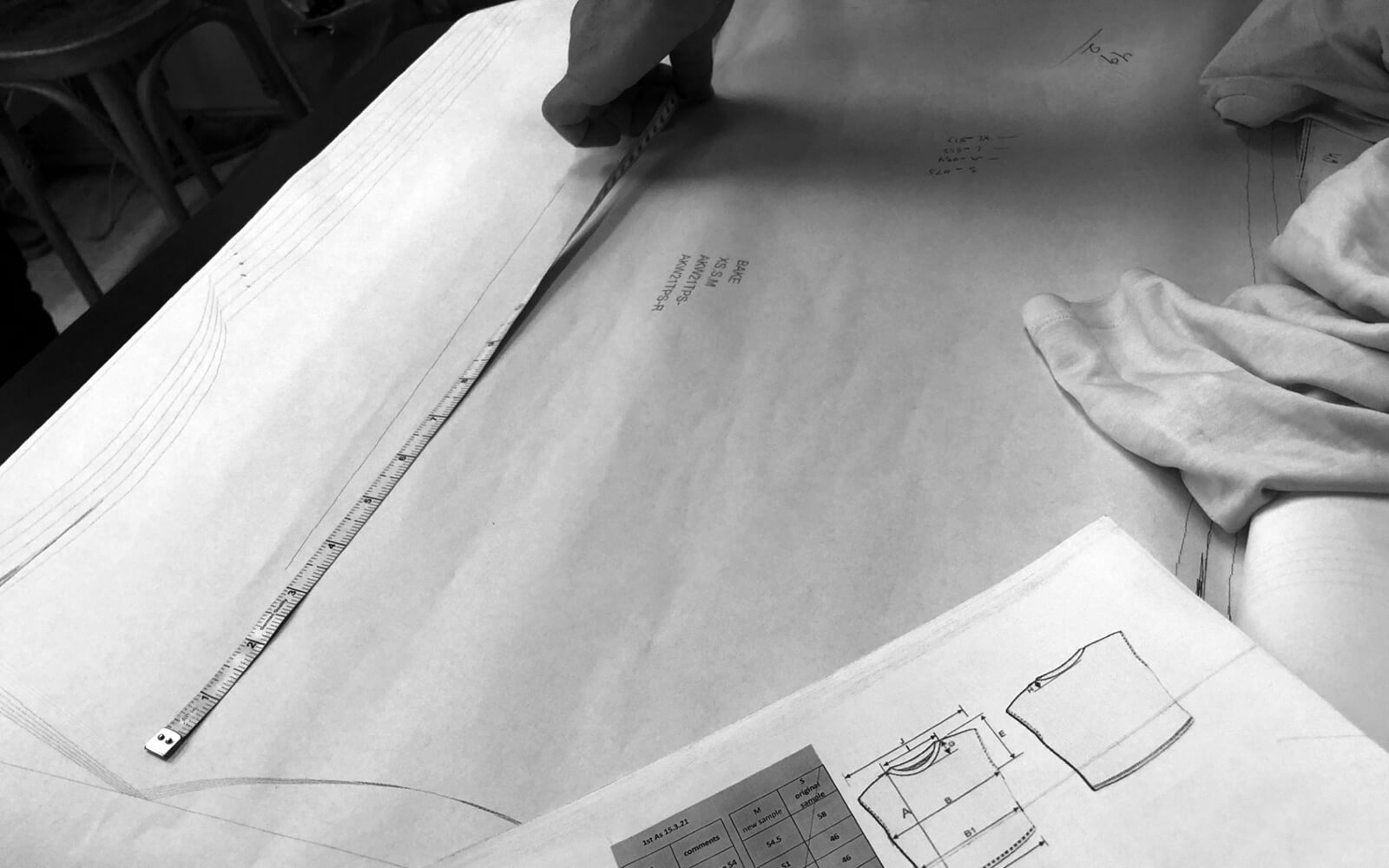

Measurement sheets are outlined for creating sketches for each model separately, and the sketches are checked before production.

Technical packs are essential in production, since they enable monitoring and checking of given details, sewing method, application instructions, colours, quantities, etc.

Quality control is the crucial segment of the process. Mistakes in sewing, overlooked details and finishing can occur due to a multitude of details and processing.

Factories often turn to engineers for advice, when dealing with a certain model for the first time or in case of complex processing. In such instances an engineer provides short training and explanation in order to facilitate production. Factories continually work with engineers throughout the entire process, so their communication during production is vital.

Towards the end of production, the ironed clothing items are checked prior to packaging. Measurements, finishing, sewing quality, print location, labels etc. are examined. If all requirements are met, the goods are packed and sent to the client.

If an audit determines that more than 10% of items do not correspond to quality standards, the entire product set is re-evaluated and proceeds to be amended.

The type of a textile item, fabric or knitted fabric is not the only element determining its placement in the suitable factory. The essential factors are quality, quantities, certificates, finishing and target pricing. Factories and their machines are classified according to diverse categories, be it knitted fabric, fabric, high quality items or fire-resistant work uniforms.

Depending on a product, we can guide you towards specialized factories for textile production (woven, knitted, non-woven), sportswear (sewn and circular woven), menswear, womenswear and childrenswear.

Technical packs are the ‘ID’ of every product and are vital to initiate the process. They contain information about material, properties, finishing, sewing, colours, size range, measurements and gradation. Technical packs enable you to determine precise dates of delivery, production duration, production course and pricing.

Having been outlined in detail, they are given to the factory, so that the initial sample can be prepared.

Once the samples have been confirmed and the dates set in the factory, production can begin. Specifications given in technical packs serve as guidelines for the entire process in the factory.

Measurement sheets are outlined for creating sketches for each model separately, and the sketches are checked before production.

Technical packs are essential in production, since they enable monitoring and checking of given details, sewing method, application instructions, colours, quantities, etc.

Quality control is the crucial segment of the process. Mistakes in sewing, overlooked details and finishing can occur due to a multitude of details and processing.

Factories often turn to engineers for advice, when dealing with a certain model for the first time or in case of complex processing. In such instances an engineer provides short training and explanation in order to facilitate production. Factories continually work with engineers throughout the entire process, so their communication during production is vital.

Towards the end of production, the ironed clothing items are checked prior to packaging. Measurements, finishing, sewing quality, print location, labels etc. are examined. If all requirements are met, the goods are packed and sent to the client.

If an audit determines that more than 10% of items do not correspond to quality standards, the entire product set is re-evaluated and proceeds to be amended.